AT ONE GLANCE

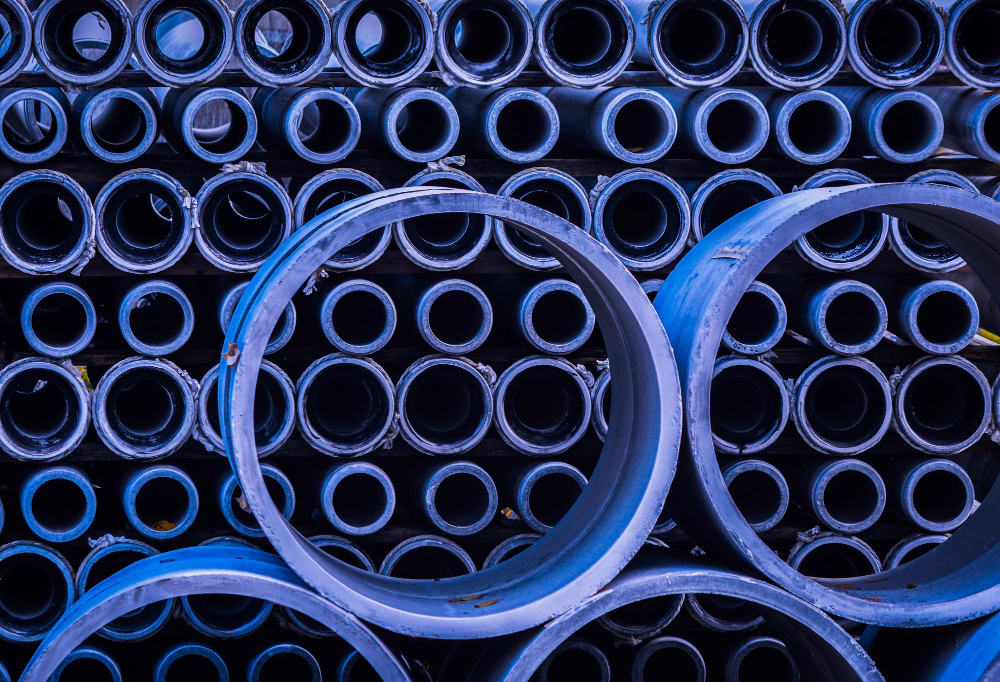

All Blue Aqua Products

Ductile Iron Pipes and fittings offer many of the robust properties of cast iron, but with enhanced performance due to the addition of magnesium. This unique composition provides Ductile Iron with exceptional ductility, a high modulus of elasticity, and superior tensile strength. These qualities make Ductile Iron an ideal choice for various applications including Drinking Water Systems, Irrigation Systems, Sewage Drainage, Rainwater Networks, and Fire-Fighting Systems.

Our Ductile Iron pipes are produced in standard lengths of 6 meters and are designed to withstand pressures ranging from gravity up to 64 bars. They are available in sizes from DN 80 mm to DN 1600 mm.

For internal protection, our pipes and fittings feature Cement Mortar Lining (Sulphate Resistant Portland Type V). Externally, they are coated with a Metallic Zinc layer followed by a bituminous paint coat for enhanced durability.

Additionally, BLUE AQUA SERVICES provides an advanced Polyurethane Internal & External Coating, offering superior high-efficiency protection for your Ductile Iron pipes.

Our Ductile Iron pipes are produced in standard lengths of 6 meters and are designed to withstand pressures ranging from gravity up to 64 bars. They are available in sizes from DN 80 mm to DN 1600 mm.

For internal protection, our pipes and fittings feature Cement Mortar Lining (Sulphate Resistant Portland Type V). Externally, they are coated with a Metallic Zinc layer followed by a bituminous paint coat for enhanced durability.

Additionally, BLUE AQUA SERVICES provides an advanced Polyurethane Internal & External Coating, offering superior high-efficiency protection for your Ductile Iron pipes.

Ductile Iron Pipes: Superior Strength and Reliability

Water Supply Pipe

Ductile Iron offers mechanical properties akin to carbon steel, including high strength, excellent ductility, and anti-corrosion performance comparable to cast iron. This combination of attributes makes Ductile Iron pipes among the safest and most reliable solutions available for water supply and drainage systems worldwide.

At Blue Aqua Service, LLC, we supply Ductile Iron pipes ranging from DN 80 to DN 2600 mm, meeting international standards such as ISO 2531/ISO 7186 and EN 545/EN 598. Our professional technical team specializes in providing tailored pipe connection solutions to meet diverse project requirements.

Our range of centrifugal Ductile Iron pipe joints includes:

XT2 St Self-Anchored Joints: Designed for DN 80 to DN 300

SIA Wb and TF Self-Anchored Joints: Suitable for DN 300 to DN 1200

BlueAqua® Self-Anchored Joints: Ideal for DN 1400 to DN 2000

Choose Blue Aqua Service for reliable, high-performance Ductile Iron pipes and expert support tailored to your needs.

At Blue Aqua Service, LLC, we supply Ductile Iron pipes ranging from DN 80 to DN 2600 mm, meeting international standards such as ISO 2531/ISO 7186 and EN 545/EN 598. Our professional technical team specializes in providing tailored pipe connection solutions to meet diverse project requirements.

Our range of centrifugal Ductile Iron pipe joints includes:

XT2 St Self-Anchored Joints: Designed for DN 80 to DN 300

SIA Wb and TF Self-Anchored Joints: Suitable for DN 300 to DN 1200

BlueAqua® Self-Anchored Joints: Ideal for DN 1400 to DN 2000

Choose Blue Aqua Service for reliable, high-performance Ductile Iron pipes and expert support tailored to your needs.

Customized External Corrosion Protection for Pipelines

Special Coated Pipes

Effective external corrosion resistance is crucial for pipelines, especially in areas with complex soil conditions. Given the diverse corrosion characteristics of soil across Oman’s expansive territory, Blue Aqua Services LLC is committed to providing tailored anti-corrosion solutions to ensure the long-term safety and durability of pipelines.

Our standard external anti-corrosion coating is a Zinc layer, offering robust protection in a wide range of soil environments. However, for regions with highly corrosive soil, additional measures are required. In such cases, we recommend using a polyethylene sleeve or specialized coatings to enhance the pipeline’s resistance to severe corrosion.

By thoroughly analyzing the soil environment and assessing its corrosive properties, Blue Aqua Services LLC designs customized anti-corrosion solutions that align with specific requirements and offer optimal cost-effectiveness. Trust us to provide the right protection strategy for your pipeline infrastructure.

Our standard external anti-corrosion coating is a Zinc layer, offering robust protection in a wide range of soil environments. However, for regions with highly corrosive soil, additional measures are required. In such cases, we recommend using a polyethylene sleeve or specialized coatings to enhance the pipeline’s resistance to severe corrosion.

By thoroughly analyzing the soil environment and assessing its corrosive properties, Blue Aqua Services LLC designs customized anti-corrosion solutions that align with specific requirements and offer optimal cost-effectiveness. Trust us to provide the right protection strategy for your pipeline infrastructure.

T-Type Joint Structure and Installation

Sewage Pipe

The T-type joint features a well-designed structure as illustrated. During installation, the external spigot compresses the rubber ring inside the socket, creating contact pressure that ensures a secure seal. This sealing function of the rubber ring maintains the joint’s integrity and prevents leakage.

Key Features:

Simple Structure: The joint is designed for ease of installation while providing reliable sealing performance.

Effective Sealing: The positioning of the sealing rings and the joint’s deflection are optimized in the socket structure design. This ensures that the joint maintains a tight seal.

Axial Flexibility: By controlling the spigot’s installation depth, the joint allows for a degree of axial flexibility. This adaptability accommodates foundation subsidence and enables pipeline steering over long distances, as demonstrated in the installation diagram.

The rubber ring used in the joint comprises two components:

Hard Rubber: Provides support and alignment for the pipe joints and requires significant thrust during installation.

Soft Rubber: Enhances the sealing capability of the joint.

Overall, the T-type joint is engineered to offer a robust and flexible solution for various pipeline installation needs.

Key Features:

Simple Structure: The joint is designed for ease of installation while providing reliable sealing performance.

Effective Sealing: The positioning of the sealing rings and the joint’s deflection are optimized in the socket structure design. This ensures that the joint maintains a tight seal.

Axial Flexibility: By controlling the spigot’s installation depth, the joint allows for a degree of axial flexibility. This adaptability accommodates foundation subsidence and enables pipeline steering over long distances, as demonstrated in the installation diagram.

The rubber ring used in the joint comprises two components:

Hard Rubber: Provides support and alignment for the pipe joints and requires significant thrust during installation.

Soft Rubber: Enhances the sealing capability of the joint.

Overall, the T-type joint is engineered to offer a robust and flexible solution for various pipeline installation needs.